Increasing pixel density capabilities have resulted in a large increase in LED display applications, and people have a greater demand for image quality. In recent years, Mini/Micro LED, which heralds a bright future for new high-definition displays, has become a hot topic in the industry. Leading LED display manufacturers have invested heavily in R&D for Mini/Micro LED and its relevant products.

The LED display industry in China has been going strong for over three decades, with the development of indoor small-pitch LED displays more than ten years ago. So, what’s the difference between Mini/Micro LED displays and the previous small-pitch LED displays? From an application perspective, Mini/Micro LED displays use smaller light-emitting elements than small-pitch LED displays, which means higher pixels per inch (PPI). This has had a far-reaching impact on the entire industrial chain, including LED driver solutions, substrates, transfer equipment, etc. It has also pushed display technology and products to a higher level. LED display applications are thus bound to expand, and this will be mainly focused on the following three application areas: The first will be large-size displays. The enormous potential of Micro LED will be felt in outdoor UHD displays, which include outdoor HD screens, high-end exhibitions, high-end meetings, and large-size Micro LED TVs, greatly improving the image quality compared to traditional large-size LED displays. Medium-size consumer applications will be the second field. Micro LED will gradually replace LCD to become the next-gen advanced display technology of OLED and will be applied in wearables, PC displays, and high-end TVs, among others. The third involves the application of small-size micro displays such as AR, VR, and MR. As Micro LED technology evolves, the LED display market will enter an era of large-size displays and a trillion yuan market size.

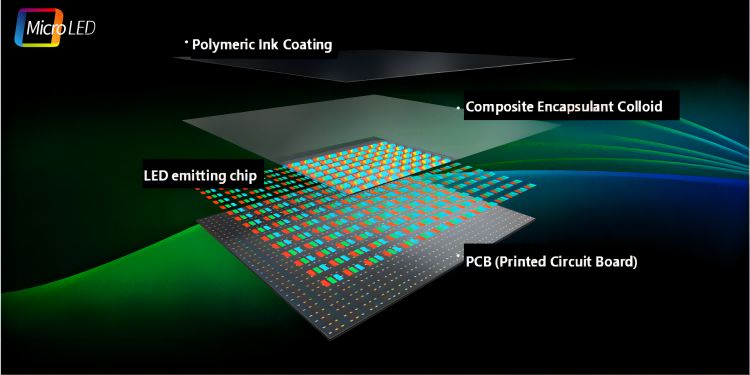

Although the market outlook is bright, the technical and product challenges should not be underestimated. First, given that Micro LED chips are so small, concerted efforts from upstream and downstream players in the industry chain are required to realize the mass transfer and then the mass production and commercialization of Micro LED displays. Second, considering Micro LED is mainly applied in sized displays based on PCB substrate, although mass production and commercialization can be achieved thanks to the mature PCB technology in large-size displays, PCB substrate cannot satisfy the need in the small and medium size display market due to the significant increase of pixel density and insufficient accuracy of PCB’s line width and warping. Glass substrate is developing quickly, and samples have been produced, but it is still not enough to achieve mass production and commercialization due to technological limits and costs. Besides, driver technology also plays a vital role in advancing the large-scale application of Micro LED in small and medium size displays. Conventional small-pitch LED driver solutions are not yet able to achieve the application of Micro LED in small and medium size displays that have a higher PPI. At present, three main LED driver solutions have been applied to Mini/Micro LED displays.

PM Driver

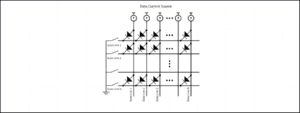

The PM (passive matrix) driver connects the P-electrode of each column of LEDs in the LED display array to the data current source, and the N-electrode of each row of LED to the scan line. When a particular column Y and a row X are gated, the LED at the intersection point (X, Y) lights up. The entire LED screen is lit in this way by high-speed point-by-point scanning, avoiding the visual persistence of the human eye, and ultimately displaying images, as shown in Fig. 1.

This kind of PM point-by-point scanning mode is easier to achieve, but PCB is characterized by a complicated wiring design and LEDs are illuminated in a cyclic, high-speed scanning manner, which shortens the illumination time and results in low brightness efficiency. Moreover, due to the complicated design of scanning circuits, having too many resistors and capacitors may lead to interpixel crosstalk, thus setting a higher requirement for the frequency of scanning signals. This is a challenge for driver technology– that it cannot make the application of Micro LED possible in small and medium size displays with high PPI.

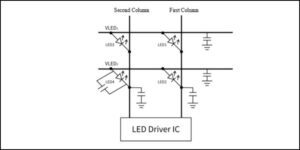

- Compared to traditional small-pitch LED displays, pixel density sees a significant increase in Mini/Micro LED displays, and more LED light-emitting elements are designed. So how do we effectively control so many light-emitting elements? The most common solution is the highly integrated driver IC with multiple-channel and high-scan support ranging from 16-scan, 32-scan, 64-scan, and even 96-scan. Only increasing the number of scans may not be enough because it is difficult for a substrate with a limited area to accommodate too many driver ICs. Thus, driver ICs with more than 16 channels emerged to provide support for the presence of LED displays with higher definition.

- At present, the PM high-scan, multi-channel, small-pitch LED driver solutions are not yet able to solve the problems of low luminance, low-grey non-uniformity, coupling under high contrast, and so on. These problems are mainly caused by stray capacitance. The layout circuits can be adjusted in the design phase of PCB to reduce the size of stray capacitance. At the same time, the smaller the pixel pitch, the denser the PCB circuits, and the more evident the effect of stray capacitance. As such, driver solutions are very important and PCB design can also not be ignored. See Fig. 2.

AM Driver

The study on AM (active matrix) drivers came about as in-depth research on Micro LEDs appeared because PM drivers struggle to satisfy the trial application of Micro LED in displays with higher PPI such as COG (chip on glass). If AM drivers are compared to a multiple-unit train with each unit self-powered to maximize the brightness utilization ratio of Micro LED, PE (pin electronics) drivers can be compared to a green-skin train with the power being transmitted from the locomotive to other train carriages. PM drivers light LEDs in a cyclic high-speed manner via point-by-point scanning, which features low display brightness efficiency and unstable image display. These characteristics make it difficult for small and medium size Micro LEDs to grow in the consumer market. On the whole, AM drivers can better support the development of Micro LED displays with higher PPI and realize more stable image displays featuring higher and more even brightness, lower power consumption, and higher contrast ratio. It is predicted that AM drivers will be a better driver solution for the application of Micro LED in small and medium size displays for mass production and commercialization purposes.

“Semi-active” Driver

Semi-active drivers use single-crystal transistors for the driver circuit of Micro-LED pixels, which can avoid interpixel crosstalk. This driver solution is, in effect, a compromise between PM and AM drivers, and has the advantages of both PM and AM drivers. It is seldom used in LED displays currently, but will or may gain a certain market share, as upstream and downstream players in the industry continue researching the commercial application of Micro LED.

That concludes the analysis of the current application of Mini/Micro LED displays, the three common driver solutions for Micro LED, and their advantages and disadvantages. Players in the industry will make their choice for large, medium, or small-size displays based on the maturity of technology, mass production, and price. However, considering the rapid development of Mini/Micro LED display technologies and products, and the UHD development trend featuring high definition, HQ image, and lower power consumption, we believe that AM drivers will become the major driver technology for promoting the application of Mini/Micro LED in small and medium size displays.